|

Sheet-Feeding Paper Bag Making Machine

PPR960C Sheet-feeding Paper Bag

Making Machine

TECHNICAL SPECIFICATION--

Dimension:14m(L)×1.7m(W)×1.9m(H)

Power:14KW, 380V Weight: 10T

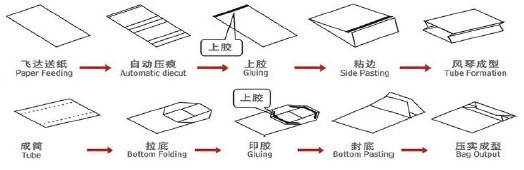

1)Working

Procedure

2)Range for Machining

● Suitable for making all kind of medium & top grade paper bags, mass production.

●

Specification:Max

sheet: 960×540mm(L×W)

Min sheet: 540×350mm(L×W)

Sheet weight(length):100g×210g(250g)

Bottom width:80mm~150mm

Bag length:180mm~330mm

Speed:50~70bags/min

Suitable Paper: Kraft paper, art paper, white board, white cardboard, laminated

paper etc.

3)Machine Features:

●

Enhanced pre-stack paper feeder, non-stop feeding.

●

Screw

rod adjustment, saving time for adjusting different paper sizes.

●

Right

side pasting& Left side pasting . Different side pasting is alternative

● Light, mechanic,

electric, gas integrated control system

Counter& defective products detection system

●

Glue

Option

:Equipped

devices with two kinds of glue, please alternatively use them.

a. Water soluble glue

(Roller gluing system)

b.Hot-melt

(Hot-melt

spray gun system)

●

HMI

digital control panel, touch screen adjustment

●

Imported PLC insures accurate

HMI digital control ,control of creasing, bottom-folding, position.

Data management solution with advanced function brings convenience.

4)Use

of this machine compared with manual working (Production, Supplies, Quality)

●

This

machine is good for mass production of paper bags.

By one

such machine,33000 bags per day (8 hours), 1 skillful operators plus 1 assistant

is enough. Each month saving labor cost: 22 persons×3000RMB=66000RMB.

●

Uniform sizing, less glue and no glue spray out, with the surface clean

and smooth.

●

This

machine helps you save a lot time.

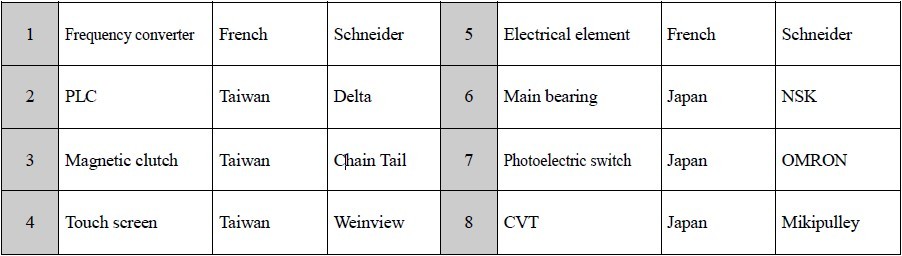

5) PART LISTS

|